How It All Began & Kept on Growing

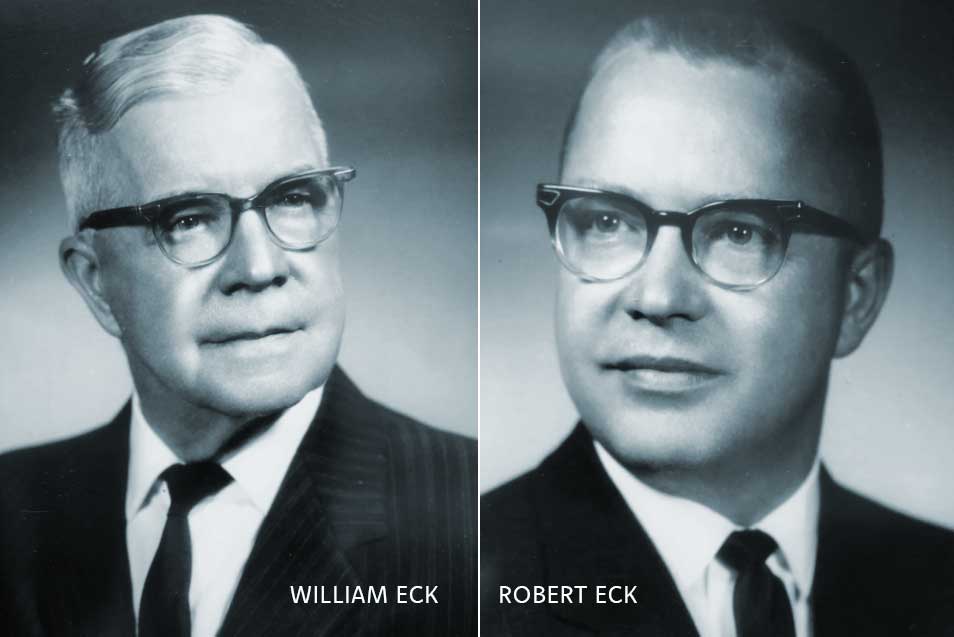

Eck purchased Kasper Construction Company’s garage on two and one-half acres just north of Manitowoc’s city limits. The first castings were produced in October 1948 for the Burpee Can Sealer Company. The business was built on orders from Harley-Davidson, Wisconsin Motors, West Bend Outboard and Johnson Motors. As the business expanded, Gordon Davidson, William Davidson and Godfrey Morton became shareholders of Eck.

Through the 1950’s, Eck became active in aircraft computer castings for A.C. Electric and experienced a period of substantial growth with the addition of permanent mold and dry sand molding capabilities.

In 1962, Eck acquired controlling interest and later complete ownership of Scherer Die Casting in Cedarburg, Wisconsin at which time it added low pressure permanent mold to its die casting capabilities. With new management, Scherer’s name was changed to Great Lakes Die Casting and ten years later to Pressure Cast, Ltd.

In 1975, the majority of the outside shareholders, now numbering twenty and controlling 80% of the shares, advised Eck management that they wanted to sell their interest and would offer their shares to Eck first. Eck family and management regained a majority in ownership which still remains today.

During the late 1970s and early 1980s, several substantial expansions were made to the plant and land purchases were made which expanded the property to 80 acres.

On July 1, 1984, a major fire at Eck destroyed over one-third of Eck’s buildings and equipment. With 60 employees and volunteers, the remaining plant was made ready and resumed operations a week later. Cooperation of state and local government agencies, an architect and construction firm enabled the company to be in replacement facilities within six months.

In 1987, an addition was added to the plant that was designed to produce die castings and low pressure permanent mold castings. In 1988, the transfer of Pressure Cast production to Eck’s new facilities was completed and Pressure Cast became an inactive corporation.

In 1992, as part of Mercury Marine’s supplier consolidation, over 100 dies were moved to Eck. A large die storage building was added for die storage and maintenance.

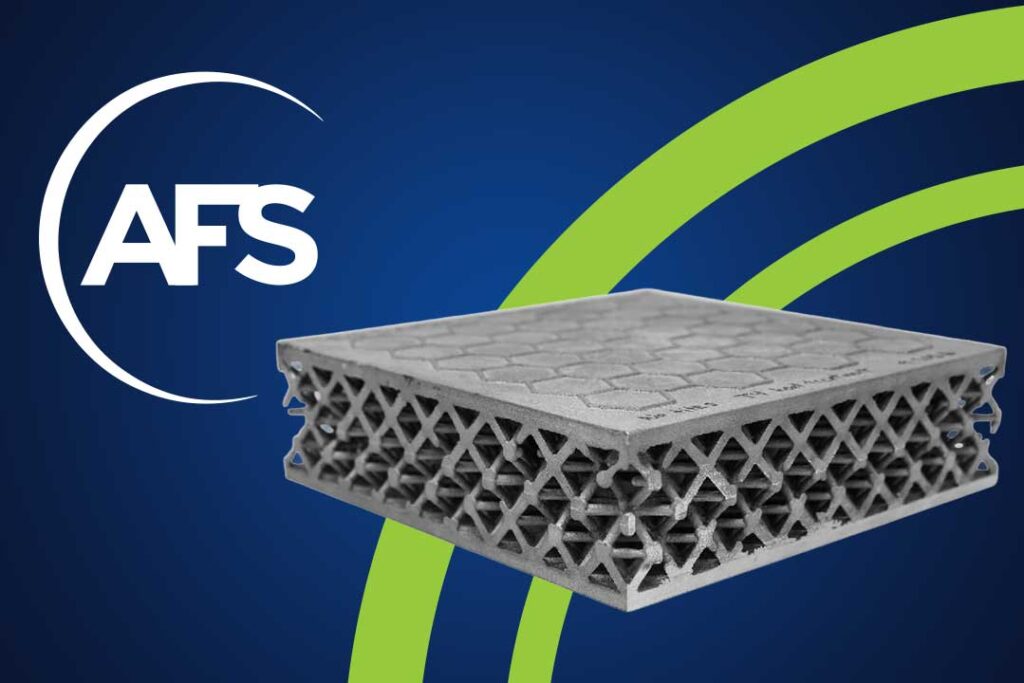

In 2007, die casting operations were phased out and replaced with a complete dry sand molding loop, additional melt capacity, thermal sand reclamation and a knockout area.

From 1948 to 2010 Eck has gone from operating in a 7,200 square foot garage with 8 employees and 5 customers to a plant with 210,000 square feet, over 250 employees and 110 customers.

In 2016, the business transitioned to the 4th generation of the Eck family as Kiley Eck Hayon became president.

In 2018, the large dry sand molding line was automated incorporating one of the largest mold rollover machines in the aluminum foundry industry.

In 2020, multiple cells were installed utilizing robotics for both pouring and casting cleaning.